Plastic Strapping Machines: Secure, Efficient, and Future-Ready

These industrial strapping machines deliver consistent tension and work seamlessly with PET and PP strapping materials, including PET plastic strapping rolls, to keep your products secure during transit and storage. Designed for efficiency and ease of use, our machines help reduce manual effort, improve packaging speed, and ensure long-term durability. It’s why businesses across India continue to trust Dipack for dependable strapping solutions.

These industrial strapping machines offer consistent tension, accommodate PET Plastic Strapping Rolls and PP straps, and ensure that your products always remain secure during the shipment phase or storage. Our machines are designed for efficiency, ease of use, along with long-term durability. Moreover, these machines lessen manual labor, improve packaging speed, and reduce operational costs. We’re trusted by numerous businesses across India.

Plastic Strapping Systems

Industrial strapping plays a crucial role in securing and bundling products for storage, shipping, and distribution. It provides several significant benefits:

Strength and Durability: Plastic strapping is strong and durable, capable of securing heavy loads and withstanding the rigors of transportation and handling.

Cost-Effectiveness: Compared to other materials like steel, plastic strapping is often more cost-effective, making it a popular choice for many industries.

Flexibility: Plastic strapping is flexible and can conform to the shape of the product being strapped, providing a secure hold without damaging the item.

Weather Resistance: Plastic strapping is resistant to weather conditions, making it suitable for outdoor use and long-term storage.

Ease of Use: Plastic strapping is lightweight and easy to handle, making it easier for workers to strap products quickly and efficiently.

Recyclability: Many types of plastic strapping are recyclable, making them a more environmentally friendly choice compared to other materials.

Overall, industrial plastic strapping is an essential component in the packaging and transportation industry, providing a reliable and cost-effective solution for securing products.

Semi vs. Fully Automatic Plastic Strapping Machine

| Features | Semi Automatic | Fully-Automatic |

|---|---|---|

| Operator Involvement | Does need manual loading or/unloading; perfectly ideal for medium volume businesses. | Minimum human intervention; auto-detection of loads for 24/7 operation. |

| Speed | 6 to 10 straps/ minute. | Around 12 straps/minute. |

| Cost & Scalability | Budget-friendly & suited for SMEs. | Higher ROI and for large-scale industries. |

| Ideal Use Case | Customized packaging or for irregular production schedules. | Continuous logistics support for - Automotive, FMCG applications. |

Our Product

Automatic Carton Strapping & Sealing Machine

Automatic box strapping and sealing machines are sophisticated packaging systems that streamline the packaging process. These machines automatically feed, strap, and seal boxes, increasing efficiency and consistency in packaging operations. They often feature adjustable settings for strap tension, speed, and sealing temperature to accommodate different box sizes and packaging needs. Safety features and easy operation make them ideal for high-volume packaging environments.

Offline Automatic Strapping Machine

Box strapping machines automate the strapping process with adjustable tension and variable speed control, accommodating different strap widths and materials. They feature heat sealing mechanisms with safety features and easy operation/maintenance, making them efficient and essential for secure packaging in diverse industries.

| Model | XT-101 | TP-6000 |

|---|---|---|

| Arch Size | 850x600 mm | 850x600 mm |

| Power | 3 Phase | 3 Phase |

| Strap Width | 9/12 mm | 9/12 mm |

| Tension | 15-70 Kgs | 10-70 Kgs |

| Speed | 2.2 sec/strap | 2.2 sec/strap |

| Dimensions | 55"x25"x58" | 56"x24"x61" |

| Weight | 200 Kgs | 210 Kgs |

Automatic Box Strapping Machine

Box strapping machines automate the strapping process with adjustable tension and variable speed control, accommodating different strap widths and materials. They feature heat sealing mechanisms with safety features and easy operation/maintenance, making them efficient and essential for secure packaging in diverse industries.

| Model | DC-700 | PW-207/316 |

|---|---|---|

| Power | 1 Phase, 250 W | 1 Phase |

| Strap Width | 6-15 mm | 6-15 mm |

| Tension | 15-60 Kgs | 15-60 Kgs |

| Speed | 2.5 sec/strap | 2.5 sec/strap |

| Dimensions | 36"x23"x31" | 36"x23"x30" |

| Weight | 100 Kgs | 100 Kgs |

Semi Automatic Box Strapping Machine

Semi-automatic strapping machines are essential in industries for their efficiency, consistency, cost-effectiveness, versatility, and ease of use. They improve packaging operations by reducing manual labor, ensuring secure strapping, and offering flexibility in handling various package sizes and types.

| Model | KZB-1 | EXS-306 |

|---|---|---|

| Power | 1 Phase, 320 W | 1 Phase |

| Strap Width | 6-15 mm | 6-15 mm |

| Tension | 15-45 Kgs | 15-45 Kgs |

| Speed | 2.0 sec/strap | 2.0 sec/strap |

| Dimensions | 36"x23"x30" | 36"x23"x30" |

| Weight | 100 Kgs | 90 Kgs |

Battery Powered Strapping Tool

Battery-powered strapping tools are portable, efficient, and consistent devices used for applying plastic strapping to secure packages. They offer versatility, ease of use, and rechargeable batteries for continuous operation.

| Model | ZP-93B | ZP-97B |

|---|---|---|

| Strap Width | 12 - 16 mm | 16 - 19 mm |

| Strap Thickness | 0.65 - 1.27 mm | 0.70 - 1.27 mm |

| Tension | 2500 N (Max) | 4000 N (Max) |

| Battery | 18V, 4000mAh | 18V, 4000mAh |

| Dimensions | 13"x6"x5" | 13"x6"x5" |

| Weight | 3.4 Kgs | 3.4 Kgs |

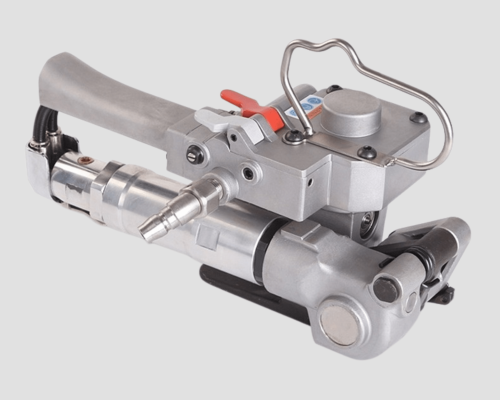

Pneumatic Powered Strapping Tool

Pneumatic plastic strapping tools are actually efficient and consistent tools powered by compressed air, used for securely strapping packages in shipping and packaging operations. They provide ease of use, versatility, and cost-effectiveness, making them essential for streamlining packaging procedures and ensuring packaging security during transit.

| Model | AQD-19 | HDAQD-19 |

|---|---|---|

| Strap Width | 12 - 19 mm | 12 - 19 mm |

| Strap Thickness | 0.60 - 1.27 mm | 0.70 - 1.27 mm |

| Tension | 2800 N (Max) | 3500 N (Max) |

| Air Supply | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Sealing | Friction Weld | Friction Weld |

| Weight | 3.4 Kgs | 3.4 Kgs |

| Dimensions | 10.8"x4.5"x5.1" | 10.8"x4.5"x5.1" |

| Weight | 3.8 Kgs | 3.8 Kgs |

Use Cases in Industry

Different industries require different packaging solutions; therefore, DIPACK, with its semi- and fully automatic strapping machine and box strapping machine, provides custom solutions for your industry needs.

Logistics & Warehousing

Securing of palletized goods through the plastic strapping systems that are designed directly for fast and long-distance shipping. The polyester (PET) straps ensure the load is stable for containers or crates, even in harsher conditions.

E-Commerce

Handling of mixed-order volumes through box strapping machines that directly adapt for varying carton sizes. Reduction of manual labor as well as ensuring tamper-proof packaging for fragile apparel or electronics.

Manufacturing

From the automatic parts for the wire reels to our automatic strapping machines that bundle heavy components for the right precision. Elimination of load shifts during delivery, thus cutting rework costs by around 30%.

Technical Specifications

- Speed: 6 to 12 straps/minute (adjustability for low/high volume needs)

- Strap Width: 12 to 16 mm (direct compatibility with PET, PP & HDPE materials) t.

- Tension Range: Around 50 to 500 N (custom ranges available for industrial-grade locking or delicate goods)

- Power Consumption: Energy-efficient plastic strapping systems reduce electricity use by around 20%.

Maintenance & Spare Parts Support

With DIPACK plastic wrapping systems, face almost zero downtime:

- 24X7 Assistance: Direct on-site support through our pan-India coverage.

- Spare parts availability: Fastest delivery of machine components in case you break something or wear and tear happens for smooth machining.

- Preventive Maintenance Services: Annual service plans for your machines to work smoothly anytime and every time.

Why Choose DIPACK?