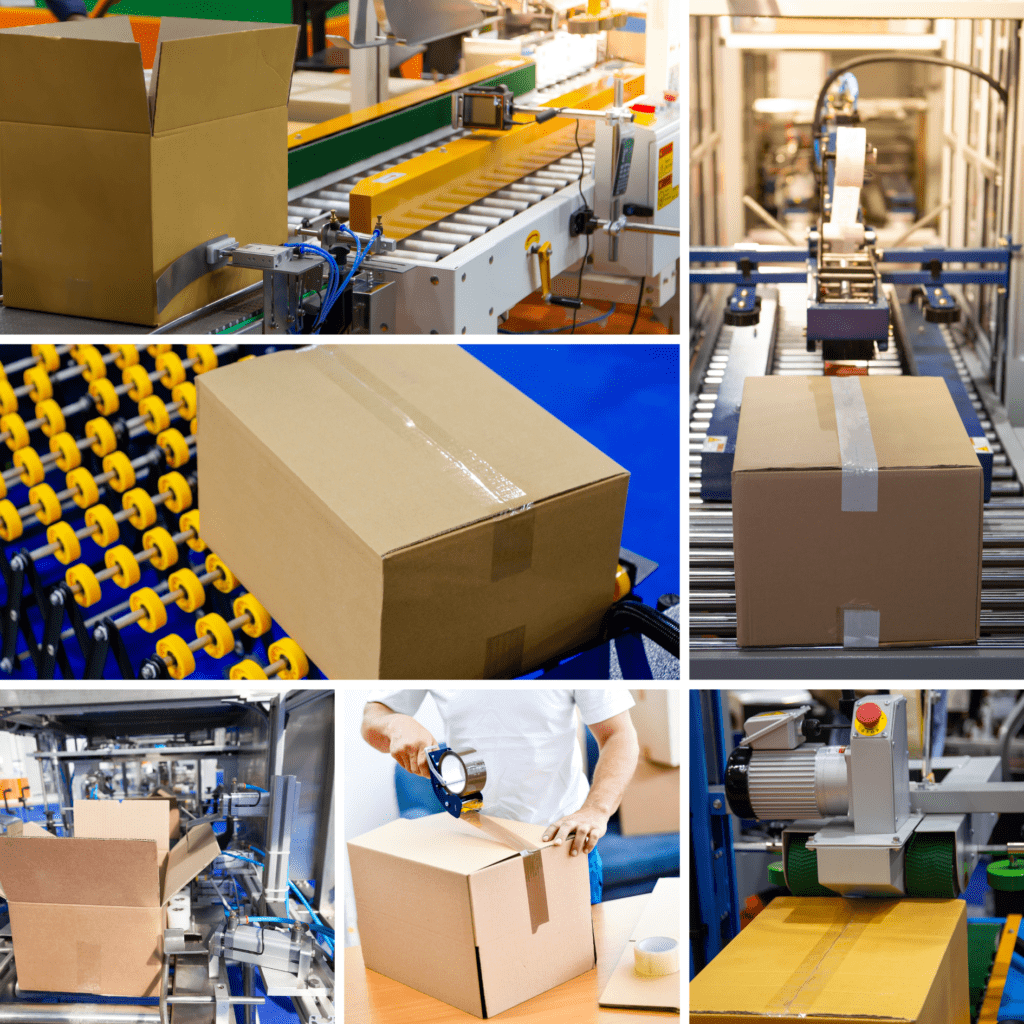

Carton Forming and Box Sealing Systems

carton forming & closing Systems

Industrial carton forming, closing, and sealing systems are crucial components in the packaging process, particularly for companies dealing with high volumes of carton packaging. Here are some of their key significances:

Efficiency: These systems automate the process of forming, closing, and sealing cartons, leading to increased efficiency and productivity compared to manual methods.

Consistency: Automated systems ensure that cartons are formed, closed, and sealed consistently, reducing the risk of errors and improving product quality.

Cost-Effectiveness: While there is an initial investment in purchasing and installing these systems, they can lead to long-term cost savings through increased efficiency and reduced labor costs.

Speed: Automated systems can form, close, and seal cartons much faster than manual methods, helping companies meet tight production deadlines.

Versatility: These systems can be adapted to work with a wide range of carton sizes and types, making them suitable for various packaging needs.

Safety: Automated systems can improve workplace safety by reducing the need for manual labor in potentially hazardous tasks.

Overall, industrial carton forming, closing, and sealing systems play a significant role in improving efficiency, consistency, and cost-effectiveness in the packaging process, making them essential for many manufacturing and distribution operations.

Automatic Case Erector and Bottom Sealer

Case erectors and bottom sealers are crucial in the packaging industry for their efficiency in forming and sealing corrugated cases. They ensure consistency, reduce labor costs, optimize space, protect products, and increase packaging output. Overall, these machines improve packaging operations’ efficiency and cost-effectiveness across industries.

Automatic Case Erector and Bottom Sealer

Case erectors and bottom sealers are crucial in the packaging industry for their efficiency in forming and sealing corrugated cases. They ensure consistency, reduce labor costs, optimize space, protect products, and increase packaging output. Overall, these machines improve packaging operations’ efficiency and cost-effectiveness across industries.

How Case Erectors Work

The Workflow

Loading

Cartons are loaded with the help of a hopper in the machine.

Forming

The box is erected for the machine with the use of vacuum suction or mechanical arms.

Sealing

Bottom flaps are shut using tape or glue.

Exit

The sealed boxes are then moved towards a different stage that’s ready for filling and then shipping.

Machine Configurations to Fit Your Needs

- Side Sealing Systems: Perfectly ideal for irregular-shaped boxes and shapes, e.g., electronics/bottles, etc. Ensuring a perfect and secure closure directly for odd-sized cartons.

- Top and Bottom Sealing: That’s perfect for direct and heavy-duty systems for FMCG logistics. Perfect and automatic sealing for both ends for durability during transit.

- Adjustable Models: quick and fast change settings that help you switch between different carton sizes in just some moments—no tools required.

Speed That Leaves Manual Packing in the Dust

Process

- Up to 30% More Efficient and Faster: From our case erectors to the last box sealing machines, these can reduce the time and be faster by around 30%.

- Zero Downtime: Vertical storage systems help operators to refill cartons without stopping production or process.

- Cost Savings: Companies directly reported saving around 26% on materials and around 34% on labor costs for post-production.

Why Automation Is Necessary (It’s not just about ROI in numbers.)

- Scalability: Handle peak season and sales demands without the need for temporary staff.

- Brand Integrity: Consistent sealed boxes that mean a lower level of damaged goods + happy customers.

- Safety: Inbuilt safety systems to prevent any kind of human injuries that can happen due to machines.

Built for Industry-Specific Demands

Our industry-leading machines are custom-designed for industry-specific needs and demands:

E-Commerce

High volume and order fulfillment that needs speed and adaptability. DIPAK’s case erectors can handle everything from the big parcels to small or uniquely shaped boxes.

Pharmaceuticals

Precision matters extremely. Our box sealing machines meet hygiene standards, thus ensuring tamper-proof, dust-free closures for the sensitive products.

Food & Beverage

From the dairy and canned products and goods, our machines can seal cartons super fast while complying with the food-grade safety systems.

Ready for the Upgrade?

From the carton forming machines or the box sealing machines to our case erector machines, these are not just tools in your company; they’re your access towards achieving a larger goal and the perfect partner in your growth journey. Whether you’re on an automation process for the first time or upgrading your legacy systems, we have the solution for your needs that fits perfectly at DIPACK.

Simply contact us for a free demo, and do check our case studies on how companies have been transformed through our machines and processes.

Simply drop your info or call us directly, and we will handle the rest from there.