In the year 2026, the demand related to packaging has evolved to a whole new level. It is driven by automation along with the need for quicker and safer logistics. Box Strapping Machines and automation machines—automated systems that secure the different systems through PET, polypropylene, or steel straps—are directly at the forefront of this transformation.

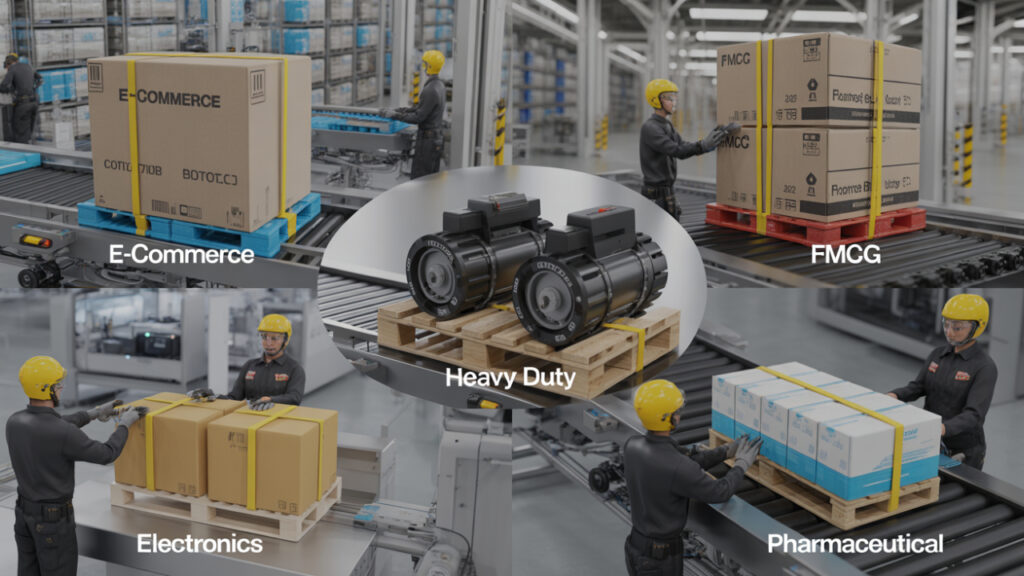

These types of industrial box strapping machines are basically no longer limited to just basic and simple bundling; they directly integrate with smarter technology, ensuring compliance with global shipping standards. From the high-volume e-commerce hubs for precision-based sensitive electronics manufacturing, their box strapping machine applications span across sectors like automotive, FMCG, and cable & wire industries. As a business prioritizes sustainability and cost-efficiency, these machines directly reduce material waste by 30% while slashing labor hours.

Choosing a suitable belting solution adjusted to specific needs in industry is critical—and knowing the different uses of box strapping equipment helps groups future-proof their packing workflows.

Auto Parts Packaging

Machine Type: Heavy-duty automatic strapping machines

The automotive industry directly relies on robust packaging for those bulky parts like the irregularly shaped parts for transmission, engine, and metal components. Automatic strapping machines for high-tensile steel directly steal, thus ensuring secure bundling, even directly for heavy loads. Machines that have strength PET or steel strapping for withstanding the harsher transit conditions, preventing the different load shifts along with the damage.

Cost & Time Saving

Eliminates manual labor, reduces material waste, and speeds up loading and unloading—these are the uses of box strapping machine. For instance, a single machine can strap up to twenty pallets every hour, saving packaging time by 50%. Brands that use these methods quote up to 35% less expensive logistical costs due to decreased rework and claims.

Electronics Manufacturing

Machine Type: Semi-automatic strapping machines with precision control

Delicate electronics like circuit boards, consumer gadgets, and servers do require soft, gentle, and secure packaging. These semi-automatic machines help operators adjust different tension levels and prevent damage during transit. A high-speed automatic model thus ensures that strap tension is consistent while directly integrating with different conveyor systems for faster workflow.

Cost & Time Savings

Reduction in human error and also ensures the consistent seal quality for big conveyor systems. Companies can directly save around 30% on packaging material while working on faster delivery schedules through the use of industrial box strapping machines.

Advanced models generally handle any kind of irregular and uniquely shaped cartons and increase efficiency.

FMCG Logistics

Machine Type: High-speed automatic strapping systems

FMCG Industry, or fast-moving consumer goods, generally demands fast-speed packaging for perishable goods, household items, or beverages. Fast and high-speed machines handle these kinds of demands for thousands of boxes every day, compatible directly with polypropylene or the PET straps for durability. A fully automatic system directly uses a single camera for faster, cost-effective operation.

Machine Type: High-speed automatic strapping systems

FMCG Industry, or fast-moving consumer goods, generally demands fast-speed packaging for perishable goods, household items, or beverages. Fast and high-speed machines handle these kinds of demands for thousands of boxes every day, compatible directly with polypropylene or the PET straps for durability. A fully automatic system directly uses a single camera for faster, cost-effective operation.

Cost & Time Savings

Cost and time savings: Automates routine procedures, lowers downtime, and allows 24/7 operations. Brands state 40% quicker shipping and lowered breakage rates, which immediately increases profitability. Systems like the Trans Pack heavy-duty machine work at 27 straps per minute, providing scalability for large-scale businesses. These are the box strapping machine applications.

E-commerce Warehouses

Machine Type: Versatile strapping machines with adjustable settings

E-commerce handles diverse product sizes, from small-sized parcels to bigger and larger appliances. The adjustable machines generally adapt to different box lengths, thus ensuring secure sealing without any kind of overstrapping. The uses of box strapping machine role in automating order fulfillment and reducing any kind of manual intervention.

Cost & Time Savings

Acceleration of order fulfillment directly reduces material costs by around 25% and lowers injury risks linked to strapping. Integration of the AI-driven warehouse systems further optimizes efficiency and helps in real-time tracking of packaging metrics.

Wire & Cable Industries

Machine Type: Industrial box strapping machines with corrosion-resistant components

Coiled cables and wires are heavy and subject to shifting in transit. The bundles stay intact throughout delivery over long distances because of specialized machinery that includes rustproof blades and high-tension bands. The machine systems have been developed for harsh environments and blend corrosion resistance with steel strapping durability.

Cost & Time Savings

Extending the lifespan of straps and reducing manual work helps ensure compliance with international shipping standards. Manufacturers can save around 20% of costs during logistics on an annual basis. More machines can further increase the efficiency and the reliability for any kind of wire product.

Why Choose DIPACK for Your Box Strapping Machines Needs?

Dipak, a trustworthy brand for decades, provides the uses of box strapping machine that can be used for different industries. From manual systems to fully automated systems, our solutions are designed for efficiency, customization, and high durability. Explore our range of different box strapping machines for different industrial purposes.

Are you ready to upgrade and increase the efficiency of your packaging lines? Contact Dipack today and simply contact Dipack and get this handled.