Stretch Wrapping Machine Systems

Stretch Wrapping Machines for Strong & Reliable Packaging

Our Stretch Wrapping Machine range is especially designed to deliver reliable load stability, faster packaging cycles, and consistent wrapping quality across industrial operations. These machines are built for demanding environments. Each stretch wrap machine ensures strong product containment, protects goods from dust and transit damage, while improving overall safety during storage and movement. From heavy-duty pallet wrapping machines to precise carton stretch wrapping machines, our system truly supports numerous packaging needs without even compromising efficiency.

Our Stretch Wrapping Machines and Systems

Explore our most innovative stretch film wrapping machine systems from DIPACK:

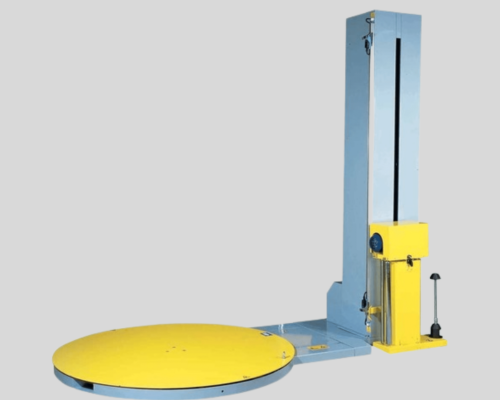

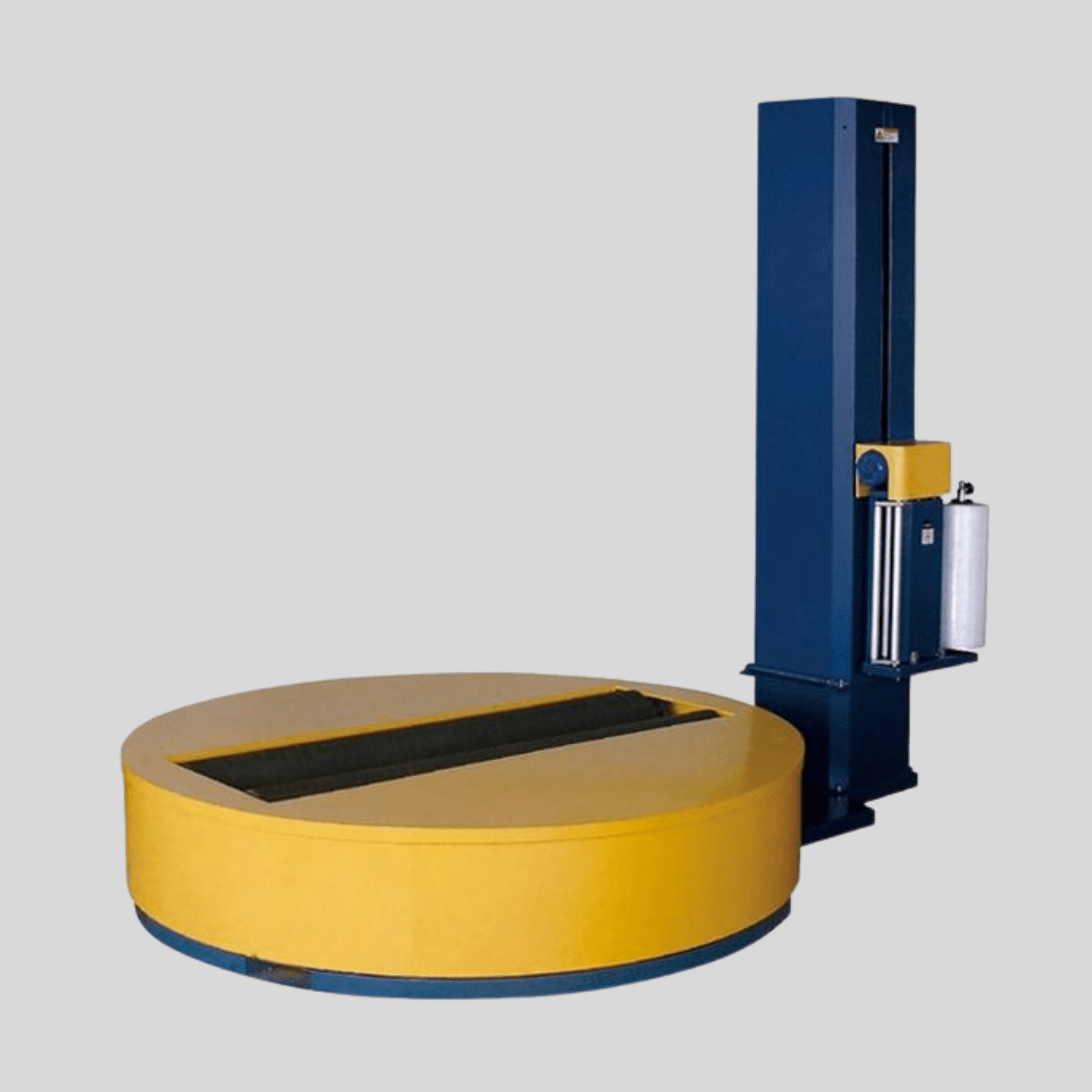

Revolving Pallet Wrapping Machine

The Revolving Pallet Wrapping Machine is great for securing heavy and unstable loads with uniform film tension. This stretch wrapping machine ensures consistent pallet stability, lessens film wastage, and improves overall load safety during the storage and transportation phase. It’s popularly being used in FMCG, logistics, and manufacturing warehouses.

| Model | PW-1650 | PW-1800 | PW-2000 |

|---|---|---|---|

| Turnplate Dia | 1650 mm | 1800 mm | 2000 mm |

| Load Height | 2200 mm | 2500 mm | 3000 mm |

| Load Weight | 1000 Kgs | 2000 Kgs | 2500 Kgs |

| Controls | PLC | PLC | PLC |

| Dimensions | 102×65×91 | 110×71×102 | 118×79×122 |

| Stretch Capacity | 300% | 300% | 300% |

| Power | 2.5 hp | 3 hp | 3.5 hp |

| Packing Speed | 20/hr | 20/hr | 20/hr |

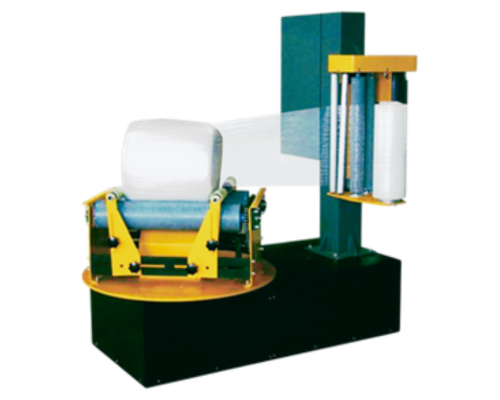

Roll Stretch Wrapping Machine

The Revolving Pallet Wrapping Machine is great for securing heavy and unstable loads with uniform film tension. This stretch wrapping machine ensures consistent pallet stability, lessens film wastage, and improves overall load safety during the storage and transportation phase. It’s popularly being used in FMCG, logistics, and manufacturing warehouses.

| Model | RW-20 | RW-20E |

|---|---|---|

| Roller Width | 600 mm | 3000 mm |

| Load Height | 600 mm | 1000 mm |

| Load Weight | 50 Kgs | 2000 Kgs |

| Controls | Timer | Timer |

| Dimensions | 47"x33"x47" | 157"x39"x78" |

| Stretch Capacity | 250% | 150% |

| Power | 1.5 hp, 1 Phase | 1 hp, 1 Phase |

| Packing Speed | 60 Rolls/hour | 60 Rolls/hour |

Fully Automatic Inline Pallet Wrapper

The Fully Automatic Inline Pallet Wrapper seamlessly gets integrated into high-speed production lines. Furthermore, it also automates load detection, wrapping, and transfer, and helps industries get faster throughput, reduced manual effort, along with consistent packaging quality across ongoing operations in large warehouses and factories.

| Model | IPW-1650 |

|---|---|

| Load Height | 2200 mm |

| Load Weight | 2000 kgs |

| Conveyor Type | Powered Roller Conveyor |

| In/Out Conveyor Size | 1800 x 1800 mm |

| Controls | PLC Controlled |

| Dimensions | 102"x65"x91" |

| Stretch Capacity | 300% |

| Power | 2 hp, 3 Phase |

| Packing Speed | 30 Pallets/hour |

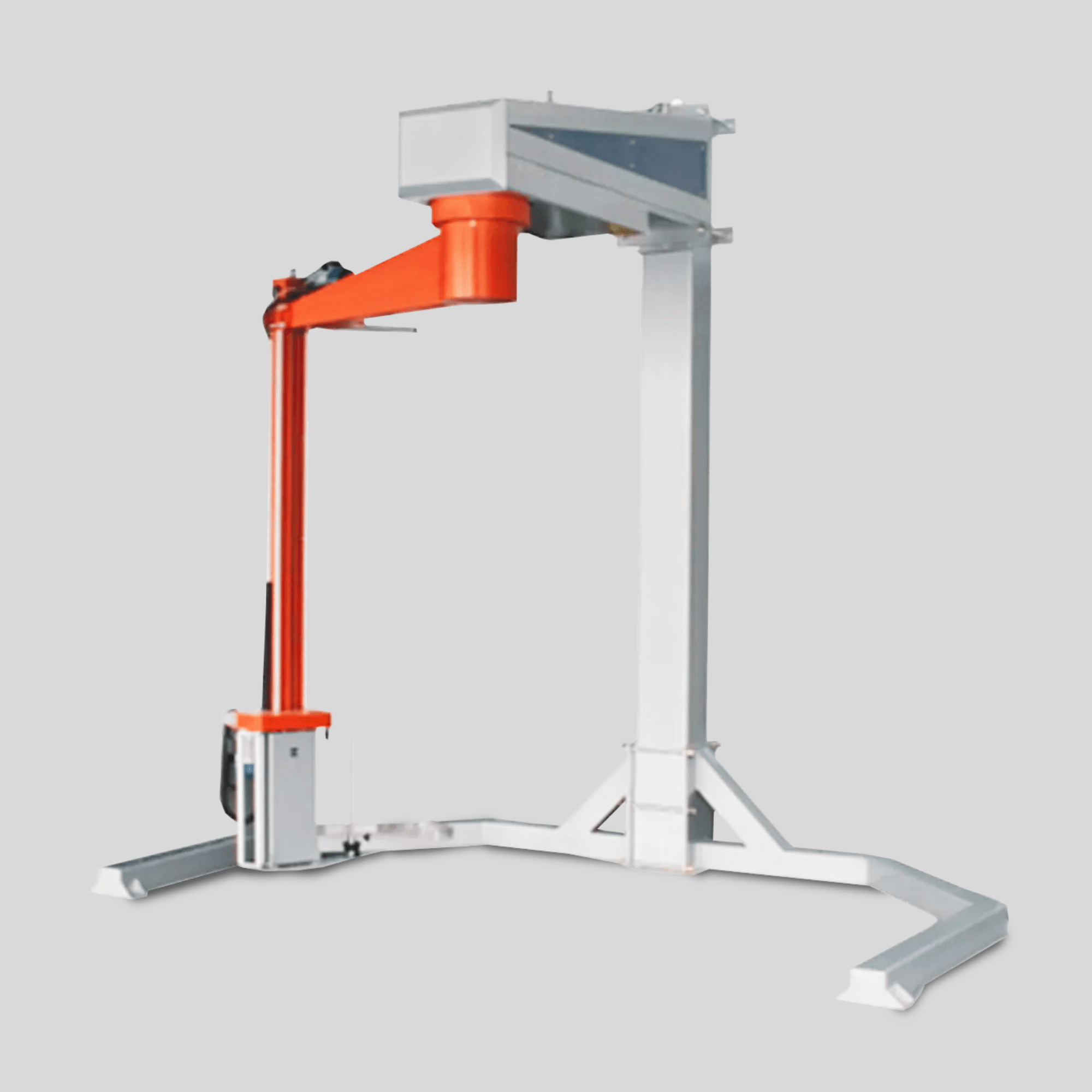

Robot Pallet Wrapper

A Robot Pallet Wrapper offers unmatched flexibility for different pallet sizes and layouts. This wrap machine smoothly moves around stationery loads, and this feature makes it a perfect alternative for dynamic warehouse environments. Moreover, it ensures stable wrapping, reduces space needs, and supports efficient packaging without a fixed installation.

| Model | XT-4510 |

|---|---|

| Max Pallet Size | No Limit |

| Load Height | 2100 mm |

| Min Pallet Size | 600 x 600 mm |

| Controls | PLC Controlled |

| Dimensions | 58"x46"x87" |

| Stretch Capacity | 300% |

| Power | 100 Ah x 2, 12v |

| Packing Speed | 60 mtrs/min |

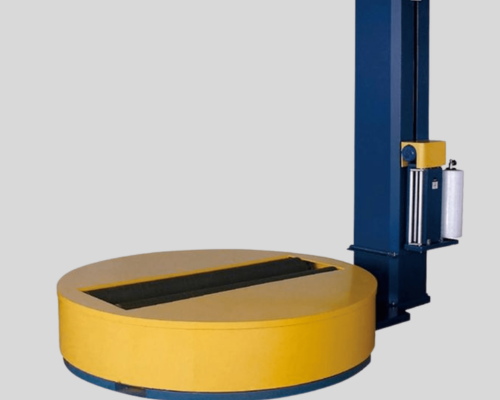

Pallet Stretch Wrapping Machine (Rotary Arm)

The Rotary Arm Pallet Stretch Wrapping Machine is the best alternative for lightweight loads and also can also be used for unstable loads. It rotates the arm rather than the pallet. This stretch wrap machine reduces load movement and delivers secure wrapping, improved safety, as well as consistent film application in high-speed industrial settings.

| Model | RPW-1800 |

|---|---|

| Max Pallet Size | 1200 x 1200 mm |

| Load Height | 2500 mm |

| Min Pallet Size | 900 x 900 mm |

| Controls | PLC Controlled |

| Dimensions | 120"x100"x120" |

| Stretch Capacity | 300% |

| Power | 3 hp, 3 Phase |

| Packing Speed | 30 Pallets/hour |

Pallet Stretch Wrapping Machine (Rotary Arm)

Using a rotating film carriage around a stationary pallet, thus ensuring stability for the irregular or lightweight loads for wrapping.

| Model | RPW-1800 |

|---|---|

| Max Pallet Size | 1200 x 1200 mm |

| Load Height | 2500 mm |

| Min Pallet Size | 900 x 900 mm |

| Controls | PLC Controlled |

| Dimensions | 120"x100"x120" |

| Stretch Capacity | 300% |

| Power | 3 hp, 3 Phase |

| Packing Speed | 30 Pallets/hour |

Reel Stretch Wrapping Machine (Axial)

Axial Reel Stretch Wrapping Machines are actually designed for long, cylindrical products like cables, pipes, and coils. This stretch wrap machine wraps products along their length and ensures strong protection, reduced handling damage, and safe transportation across demanding industrial supply chains.

| Model | RW-1650 | RW-1800 | RW-2000 |

|---|---|---|---|

| Turnplate Dia | 1650 mm | 1800 mm | 2000 mm |

| Load Height | 1500 mm | 1500 mm | 3000 mm |

| Load Weight | 1000 Kgs | 2000 Kgs | 2500 Kgs |

| Controls | PLC Controlled | PLC Controlled | PLC Controlled |

| Dimensions | 102"x65"x59" | 110"x71"x59" | 118"x79"x59" |

| Stretch Capacity | 300% | 300% | 300% |

| Power | 3 hp, 3 Phase | 4 hp, 3 Phase | 5 hp, 3 Phase |

| Packing Speed | 20 Reels/hour | 20 Reels/hour | 20 Reels/hour |

Reel Stretch Wrapping Machine (Axial)

Stretching film in an axial way for the reel’s axis for tightly wrapping cylindrical or coiled materials like wire or carpet rolls.

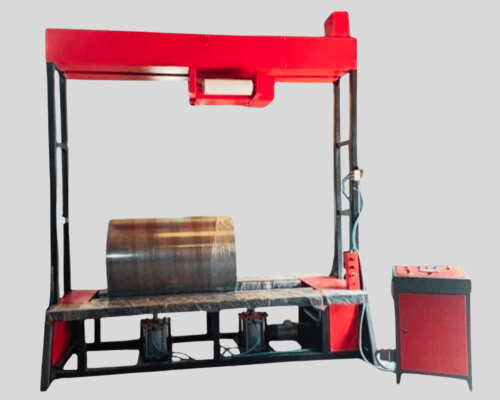

Reel Stretch Wrapping Machine (Radial)

The Radical Stretch Wrapping Machine is also used for wrapping products through their diameter, and makes it perfect for heavy reels and large rolls. This stretch wrap machine delivers uniform tension, enhanced load stability, and dependable protection for metal, wire, and industrial reel packaging applications.

| Model | RRW-1500 | RRW-2000 | RRW-3000 |

|---|---|---|---|

| Roller Width | 1500 mm | 2000 mm | 3000 mm |

| Load Height | 1000 mm | 1000 mm | 1000 mm |

| Load Weight | 1000 Kgs | 1000 Kgs | 2000 Kgs |

| Controls | PLC Controlled | PLC Controlled | PLC Controlled |

| Dimensions | 98"x39"x78" | 118"x39"x78" | 157"x39"x78" |

| Stretch Capacity | 300% | 300% | 300% |

| Power | 2.5 hp, 3 Phase | 2.5 hp, 3 Phase | 3 hp, 3 Phase |

| Packing Speed | 20 Reels/hour | 20 Reels/hour | 20 Reels/hour |

Box Stretch Wrapping Machine

The Box Stretch Wrapping Machine is perfect for compact and medium-sized cartons. Now, this carton stretch wrapping machine improves load bundling, lessens secondary packaging needs, and ensures clean, temperature-resistant wrapping for e-commerce, retail, and warehouse dispatch operations.

| Model | BW-20 | BW-30 | BW-20P |

|---|---|---|---|

| Turnplate Dia | 650 mm | 750 mm | 750 mm |

| Max Pack Size | 24"x16"x16" | 36"x24"x24" | 36"x36"x40" |

| Load Weight | 40 Kgs | 60 Kgs | 2500 Kgs |

| Controls | Timer | Timer | PLC Controlled |

| Dimensions | 47"x33"x47" | 52"x38"x60" | 118"x79"x122" |

| Stretch Capacity | 250% | 250% | 250% |

| Power | 1 hp, 1 Phase | 1 hp, 1 Phase | 1.5 hp, 3 Phase |

| Packing Speed | 80 Boxes/hour | 70 Boxes/hour | 60 Boxes/hour |

Fabric Roll Wrapping Machine

Coil Wrapping Machine

Lugguage Wrapping Machine

Orbital Wrapping Machine

Semi-Automatic vs Fully Automatic Stretch Wrap Machine

A perfect comparison table based on the different stretch wrapping systems from DIPACK to help you clarify which machine is best for your industrial applications:

| Parameters | Semi-Automatic Stretch Wrapping Machines | Fully Automatic Stretch Wrapping Machines |

|---|---|---|

| Operator Involvement | Needs manual loading/unloading & initiation (e.g., application of film tail for the load) | Low human intervention & uses sensors or photo-eyes for auto-detect of load size & optimized wrapping |

| Speed and Throughput | Slow (10–30 loads per hour); great for mid-volume needs | High-speed wrapping (around 60+ loads per hour); great for large-scale & continuous production lines |

| Cost & Setup | Low upfront cost; cost-effective generally for small-to-medium firms | Higher investment costs; good for long-term scalability and better ROIs |

| Flexibility | Multiple settings for varying loads & needs manual adjustments | Fully programmable & adaptable to multiple load types without manual intervention |

| Maintenance | Simple mechanics & easier to maintain with just basic training provided | Complex system and programming. Needs specialized services and time to time calibration |

| Ideal Applications | Small warehousing requirements & non-regular production schedules, or low budget setups | High-volume industries (e.g., FMCG, E-commerce Warehouses, automotive) needing 24X7 reliability |

Based on your needs and requirements DIPACK Solutions does provide multiple machines for your exact needs and industry requirements.

Lugguage Wrapping Machine

Orbital Wrapping Machine

Applications by Industry

FMCG

Securing beverages and snacks plus the household goods for pallets for the fastest dispatch.

Automotive

Wrapping of steel coils or engine parts or any other metal components through heavy-duty film.

Pharma

Protecting sterile medical supplies with dust-proof packaging along with tamper-proof packaging.

E-Commerce

Automation of parcel bundling or any kind of mixed order bundling.

Efficient & Reliable Stretch Wrapping Machines

Every DIPACK stretch wrapping machine is built for consistent performance in demanding industrial conditions. Designed for long operating hours and varying load types, our systems ensure strong load stability, uniform film tension, and reduced material usage.

Key benefits:

Consistent load containment

Less film wastage

Reliable performance for all load types

Easy operation with minimal supervision