How DIPACK is Revolutionizing Secondary Packaging in India?

It’s 2026 and people today aren’t only looking for good products but also good packaging. They want to make sure that companies pack their product thoughtfully to keep it safe for transport and its demand is growing rapidly.

Product packaging involves three stages- primary, secondary and tertiary. All three stages are to ensure that your customers get their packages safely, at a fair price, and with ease.

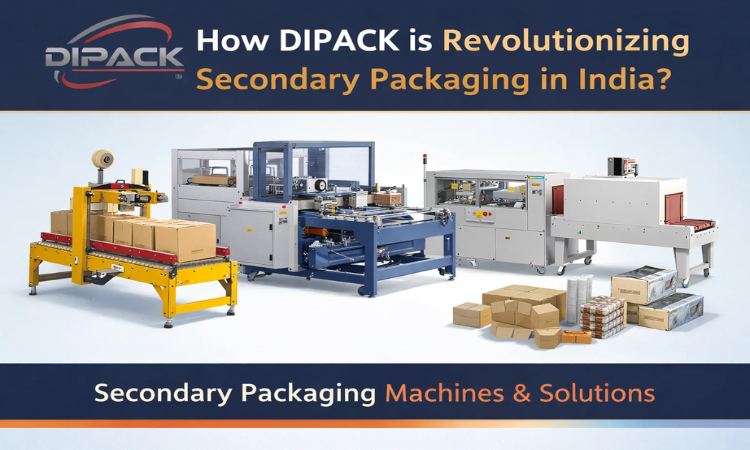

That is where DIPACK comes in. DIPACK offers secondary packaging machines and systems, providing smart, reliable, and future-ready secondary packaging solutions in India to suit your business.

Understanding Secondary Packaging Machines and Its Importance:

packaging is the immediate wrapping around products that provide instant safety to the product. Secondary packaging is putting the products in small boxes or using plastic stretch wraps to secure these before shipping. Secondary packaging solutions in India have become essential because they offer easier handling, storage, and shipping.

Examples:

- Carton sealing to pack products in boxes.

- Uses PP/PET bands (polyester straps) to bind the products.

- Using plastic films to Primary stretch/shrink wrap products for bulk transportation.

Why is this important to you?

- Secondary packaging protects your product.

- It reduces the exposure to damage, product loss, or return charges.

- It reduces the waste, percentage of manual rework and expense across the overall packaging cycle.

- A good packaging always makes your customers happier!

Neglecting secondary packaging solutions in India not only increases the risks of your products getting harmed but also creates a negative impact in your buyer’s minds. This ultimately loses you customers, missing your next sale and long-term wealth.

Overview of DIPACK’s Product Portfolio

DIPACK is your one-stop shop for all of your packaging machines. These secondary packaging machines are fit for use in different businesses, large or small. Here is what you can expect to find:

1.Stretch Wrapping Machines

This machine wraps plastic stretch films around the boxes to secure them completely against instability, dust, and moisture, and promote safe storage & shipping.

2.Shrink Tunnel Systems

It uses heat to shrink the film and tamper-seals your products that tightly packages the product and keeps it safe, and offers your product a clean & professional look.

3. Plastic Strapping Machines

DIPACK plastic strapping machines tighten robust plastic straps around cartons, parcels, or heavy materials, keep the bundles together and offer safe shipping. They come in two types:

- Semi-automatic: Requires operator to begin and end process

- Fully automatic: Capable of running on its own in a high-speed line.

- Carton erecting & sealing systems:

Carton erecting & sealing systems automatically fold boxes (cartons) into shape and seal using tape. This saves your team from hectic manual work every day.

4.Carton erecting & sealing systems:

Carton erecting & sealing systems automatically fold boxes (cartons) into shape and seal using tape. This saves your team from hectic manual work every day.

5. Consumables:

- PP/PET strapping bands: These are robust, lightweight strapping that you can apply through strapping machines.

- Stretch films: These are clingy films used for wrapping and stabilizing goods.

- Shrink films: This uses plastic that shrinks with heat and makes for a great touch packaging.

- BOPP tapes: This uses clear, strong tapes used for sealing boxes.

What Sets DIPACK Apart?

When you select DIPACK, you get access to advanced benchmark packaging technology and user-friendly experience that support your innovative business needs. Here are some reasons why DIPACK feels different.

- Innovation Design:

Every machine is designed to make complex packaging “super-simple and high-speed.” You can expect varieties of easy to use operations and decreased down time.

- Durable Performance:

Equipment such as sophisticated plastic strapping systems operate for years and require little maintenance.

- Pan-India Support:

DIPACK operates on PAN-INDIA level and therefore you get 24/7 customer support irrespective of any city. You can find spare parts easily & professional consultants to repair or buy a new device anytime required.

- Experience That Counts:

DIPACK has over thirteen years of experience and knowledge in servicing a wide variety of industries, including FMCG, pharmaceuticals, logistics industries, e-commerce, and more. Its demonstrated cost, overhead savings and increased packaging quality have shown gradual growth over the years & made customers love the brands. Choosing DIPACK is not just choosing a machine; it assures you continuous improvement and maximum return on investment in our partnership.

Real-World Applications and Industry Use Cases:

DIPACK secondary packaging machines are already solving real problems in key sectors:

1.Logistics & Warehousing:

DIPACK machines create an automatic system to make your logistic & warehouse workflow smarter and more efficient. It uses PET strapping to secure the items that offer an ideal packaging for long-distance transport, offers fully-automated & high-speed operations to both types of logistics operations- SMEs for daily packaging & large product packaging operations.

2. E-commerce:

DIPACK secondary packaging machines offer versatile box strapping, fulfilling all your personalised e-commerce requirements. It reduces the manual handling workload, sorts the products early, and increases tamper resistance for safe transportation.

3.Manufacturing:

Using DIPACK machines helps manufacturing with robust strapping for heavy items and wire reels and on-site manual working dependency by 30%.

DIPACK VS Competitors:

DIPACK is distinct, as a full system and not just machines, but also the consumables and service to keep you running. Some suppliers may sell you a machine, but DIPACK is different:

| Feature | DIPACK | Generic Suppliers |

|---|---|---|

| Machine + Consumables | Yes (integrated) | No (machines only) |

| Pan-India Demos & Support | Yes | Limited |

| Maintenance | Easily accessible and quickly scheduled | Usually reactive and may take time |

| Rapid Spares Delivery | 24/7 support, fast turnaround | Often delayed |

DIPACK helps you avoid unexpected additional costs, have complete assurance of support and be able to maximize machine uptime.

Why Choose DIPACK Now?

Here are a few reasons for you to choose DIPACK as your packaging solutions partner:

- DIPACK’s secondary packaging machines claim less packaging times, and improve your product’s safety with high-quality secondary packaging.

- DIPACK provides custom-built solutions according to your business size with reliable & modern machines with proven results in cost-savings & operational efficiency.

- All DIPACK clients receive strong after-sales support for lifetime.

- You will achieve very real and measurable results in terms of less cost, less waste, improved working efficiencies.

So are you ready to improve your secondary packaging process? Reach out to DIPACK for a free demo to see how DIPACK secondary packaging machines can transform your packaging process:

- Email: sales@dipack.in

- Phone: +91-9350471435

- Offices: Based in Delhi, serving all of India.

FAQs:

Secondary packaging is the process of sorting product items into bigger boxes that can store them in bulk. This process makes transport and storage easier, reduces damage, and assists with bulk handling.

DIPACK supplies stretch wrapping machines, shrink tunnel systems, semi-automatic and fully automatic strapping machines, and carton erecting and sealing secondary packaging machines.

Yes. DIPACK can provide demo, service, and supply spare parts wherever you are in the country.

They automate menial packaging processes, reduce the need for man power, increase speed, ensure your products arrive safely, and save you costs.

Call +91-9350471435 or complete the form on dipack.in. Our team will entertain you with an expertise & customised solution against all your queries & requirements

Call +91-9350471435 or complete the form on dipack.in. Our team will entertain you with an expertise & customised solution against all your queries & requirements